Pearl White PP Label: The Smart Choice for Modern Packaging

Feb 25,2026Why Pearl White PP Label is the Go-To Choice for Packaging

Feb 18,2026Why Inkjet Matte White PP is the New Gold Standard for Professional Durable Labeling

Feb 11,2026The Waterproof Standard: Mastering Product Branding with Inkjet Matte White PP Labels

Feb 03,2026In the tire manufacturing industry, tire labels serve as a crucial bridge of communication between consumers and manufacturers. They provide key information about a tire's performance, safety, and energy efficiency. But what exactly are these small labels, which are subjected to a variety of harsh conditions daily, made of?

The manufacturing of tire labels, or more professionally, Tyre Label Material, is a precise science. To ensure that the information remains clear and readable throughout the tire's entire lifespan, the label material must possess exceptional durability and adhesion.

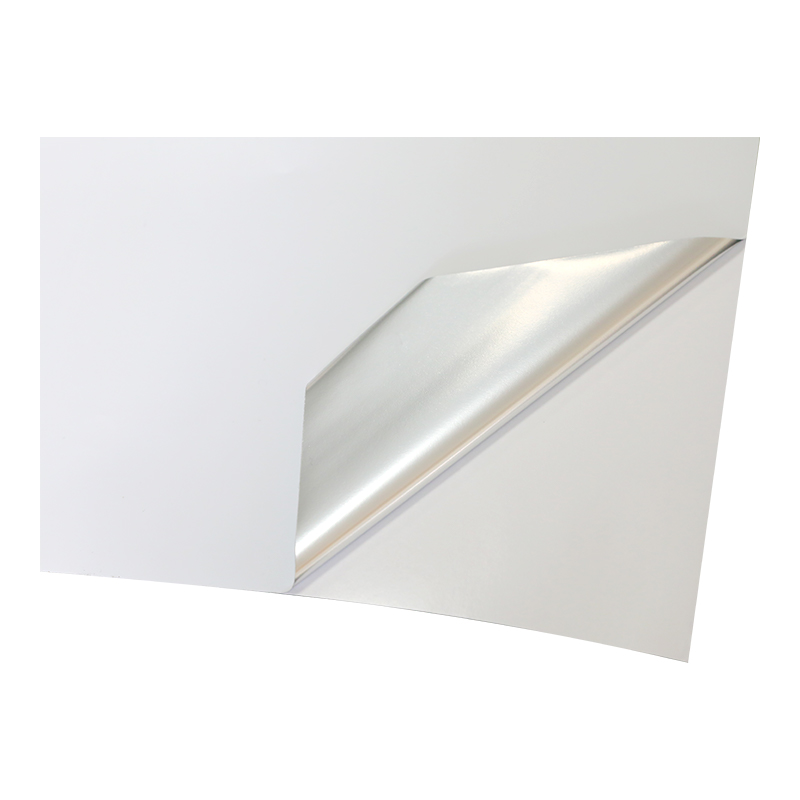

Typically, a tire label is composed of the following layers of composite material:

Face Stock: This is the outermost part of the label, where the information is printed. It needs to have excellent printability and resist abrasion, chemical corrosion, and UV radiation. Common face stocks include synthetic paper (like polypropylene or PP) or polyester (PET).

Polypropylene (PP): An economical and durable synthetic material with good moisture and chemical resistance.

Polyester (PET): A superior-performing material with excellent heat, weather, and tear resistance, often used for labels requiring high durability.

Adhesive: This is the most critical component for ensuring the label firmly adheres to the tire's surface. Tire surfaces often contain oily release agents and are uneven, which presents a challenge for adhesive selection. Therefore, a specialized high-tack, strong permanent pressure-sensitive adhesive is required. This type of adhesive can penetrate the micro-gaps on the tire's surface to form a strong bond. Some label manufacturers also use special rubber-based or acrylic-based adhesives to ensure adhesion in extreme temperatures and harsh environments.

Release Liner: This layer protects the adhesive before the label is applied. It is usually made of silicone-coated paper or a PET film, allowing the label to be easily peeled off.

The selection of these materials is not by chance; it is based on the unique challenges that tire labels (Tyre Labelling Materials) face:

High Adhesion Requirements: During manufacturing and transport, tires come into contact with chemicals like mold release agents, which can affect the stickiness of regular adhesives. A specialized high-strength adhesive is key to ensuring the label does not fall off.

Abrasion and Weather Resistance: Tires are exposed to sunlight, rain, and friction during storage and transport. The label's face stock must resist these elements to ensure the barcode and text remain clear and legible.

Printability: The label needs to be compatible with various printing technologies, such as thermal transfer printing, to ensure information is printed quickly and accurately.

In summary, a successful tire label (Tire Label Material) is more than just a sticker; it's a composite product meticulously designed and optimized with material science. From the durable face stock to the strong adhesive, every component serves to ensure the label can fulfill its mission in the demanding tire environment. This is why such a wealth of professional knowledge lies behind a seemingly simple label.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى