The Waterproof Standard: Mastering Product Branding with Inkjet Matte White PP Labels

Feb 03,2026Why Matte White PP Labels Are Becoming the Go-To Choice for Premium & Durable Packaging

Jan 27,2026Why Transparent PP Labels Are Dominating Modern Packaging Design

Jan 21,2026Why Glossy White PP Labels are the Gold Standard for Modern Product Packaging

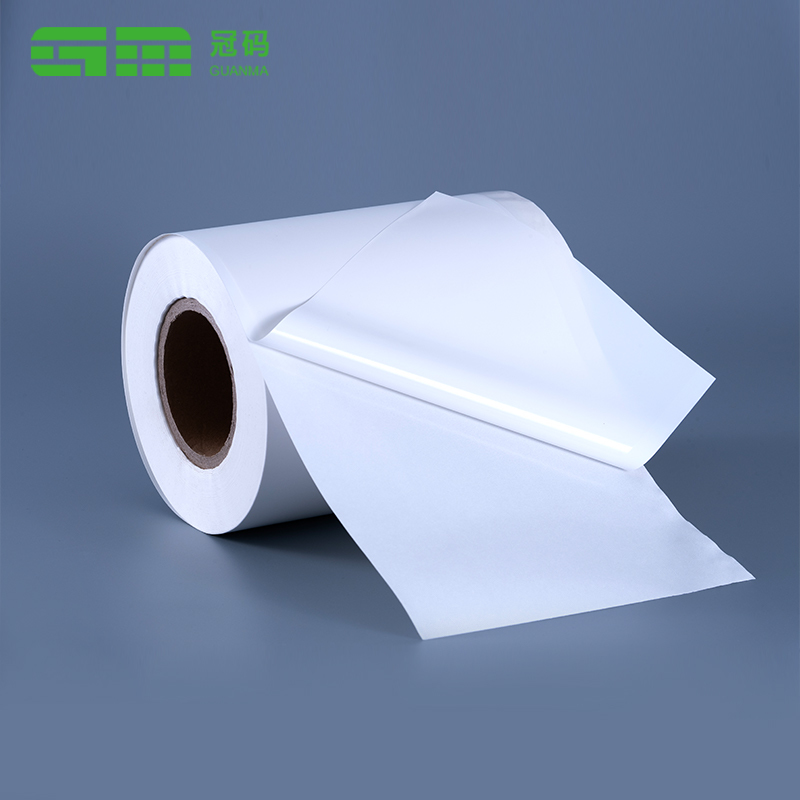

Jan 14,2026For small businesses and DIY enthusiasts, the transition from standard paper labels to synthetic materials marks a significant upgrade in product presentation. Inkjet Matte White PP (Polypropylene) labels serve as a bridge between industrial durability and home-office accessibility. Unlike standard wood-pulp paper, Polypropylene is a thermoplastic polymer. This means the substrate is essentially a thin, flexible sheet of plastic. When coated with a specialized matte reception layer designed for aqueous inkjet inks, it allows users to produce waterproof, tear-resistant labels using standard desktop printers.

The "Matte White" finish is particularly strategic for readability and scanning. While glossy labels often reflect overhead lighting, making barcodes or small ingredients lists difficult to read, a matte finish absorbs light. This provides a high-contrast background that makes text pop and colors appear deep and saturated, akin to fine art paper but with the ruggedness of plastic.

The primary driver for choosing Inkjet Matte White PP labels over standard paper is environmental resistance. In scenarios where a product might be stored in a refrigerator, bathroom, or outdoor environment, paper labels degrade quickly. They absorb moisture, wrinkle, and eventually disintegrate. PP labels, however, are hydrophobic.

A common mistake users make is treating Matte White PP like standard copy paper. Because the material is non-porous plastic with a chemical coating, it manages ink absorption differently than cellulose fibers. Using the "Plain Paper" setting on your inkjet printer will result in washed-out colors and ink that may never fully dry, leading to smearing.

To achieve a professional finish, you must force the printer to adjust its nozzle spray density. You should select a setting such as "Matte Photo Paper" or "Premium Presentation Paper Matte." These settings instruct the printer to lay down more ink for vibrancy but do so in a controlled manner that matches the drying speed of the coating. High-quality mode is recommended for text sharpness, especially for FDA-mandated ingredient lists.

While many modern pigment-based inkjet printers produce instantly dry prints on this media, older dye-based inks may require a short curing period. It is best practice to let the printed sheet sit for 5 to 10 minutes before applying the labels to containers. This ensures the chemical bond between the ink and the matte coating has set, maximizing scratch resistance.

Understanding where Inkjet Matte White PP fits in the hierarchy of labeling materials helps in justifying the cost, which is typically higher than standard paper. The table below outlines the functional differences between common inkjet label materials.

| Feature | Standard Matte Paper | Inkjet Matte White PP | Glossy Polyester |

| Base Material | Wood Pulp | Polypropylene (Plastic) | Polyester (Plastic) |

| Waterproof | No | Yes | Yes |

| Flexibility | Low (Wrinkles) | High (Conforms to curves) | Medium (Can differ) |

| Tear Resistance | None | High | Very High |

The flexibility of Polypropylene makes it uniquely suited for curved surfaces. Unlike rigid polyester labels which may try to return to their flat state (a phenomenon known as "flagging" or "winging"), Matte White PP is soft and pliable. It wraps effectively around small circumference tubes, such as lip balm containers or test tubes, without lifting at the edges.

When applying the label, ensure the surface of the container is clean and dry. While the label itself is waterproof, the adhesive bond is formed best on a dry surface. Once applied, the adhesive typically requires 24 hours to reach its maximum permanence. For products that will be submerged in ice buckets or water, applying a clear acrylic spray over the printed label can further seal the porous matte coating, rendering the ink completely impervious to running or bleeding.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى