Why Transparent PP Labels Are Dominating Modern Packaging Design

Jan 21,2026Why Glossy White PP Labels are the Gold Standard for Modern Product Packaging

Jan 14,2026Why Synthetic PP Labels Are Replacing Paper Labels in Industrial and Consumer Packaging

Jan 06,2026Enhancing Product Branding: The Ultimate Guide to High-Resolution Inkjet Coated Label Paper

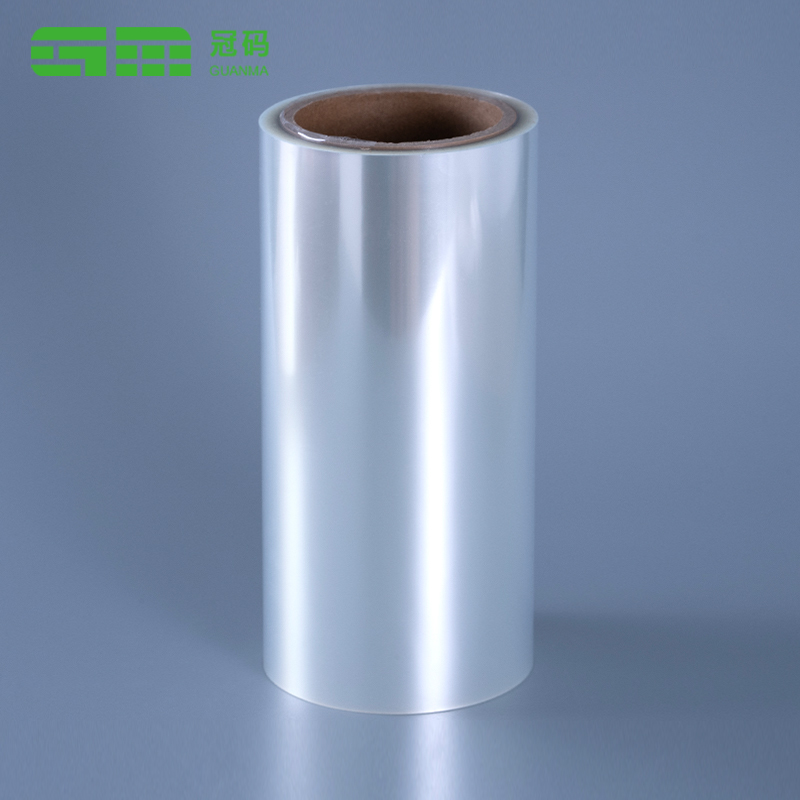

Jan 04,2026Transparent PP labels are made from polypropylene film that offers high clarity, durability, and resistance to moisture and chemicals. Unlike paper labels, they allow the original packaging material and product to remain visible, creating a “no-label look” that is increasingly favored in premium and minimalist packaging. This makes them especially suitable for industries where visual cleanliness and product authenticity are critical.

Polypropylene as a label substrate provides a balanced combination of flexibility, strength, and chemical stability. These properties ensure labels remain intact during filling, transportation, and end-use, even in challenging environments such as refrigeration or high-humidity storage.

Transparent PP labels are widely used in sectors that demand both aesthetics and durability. Their ability to blend seamlessly with packaging surfaces makes them ideal for showcasing product contents while maintaining regulatory and branding information.

To achieve optimal visual impact, transparent PP labels can be printed using flexographic, offset, or digital printing methods. White ink underprinting is often applied to enhance color opacity and contrast, while varnishes and laminations improve surface protection.

The performance of a transparent PP label depends heavily on the adhesive used. Different packaging surfaces and storage conditions require tailored adhesive solutions to ensure long-lasting adhesion without edge lifting or residue.

| Adhesive Type | Recommended Use |

| Acrylic | General-purpose, clear containers |

| Hot Melt | High-speed labeling lines |

| Freezer-grade | Cold storage and frozen products |

Transparent PP labels can support sustainability goals when designed correctly. Using compatible PP facestocks and adhesives allows the label and container to be recycled together, reducing separation issues in recycling streams. Additionally, thinner films help reduce material usage without compromising performance.

Selecting the right transparent PP label involves evaluating the product environment, branding goals, and application method. Factors such as container shape, surface energy, exposure to moisture, and regulatory requirements should all be considered to ensure optimal results and long-term reliability.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى