Pearl White PP Label: The Smart Choice for Modern Packaging

Feb 25,2026Why Pearl White PP Label is the Go-To Choice for Packaging

Feb 18,2026Why Inkjet Matte White PP is the New Gold Standard for Professional Durable Labeling

Feb 11,2026The Waterproof Standard: Mastering Product Branding with Inkjet Matte White PP Labels

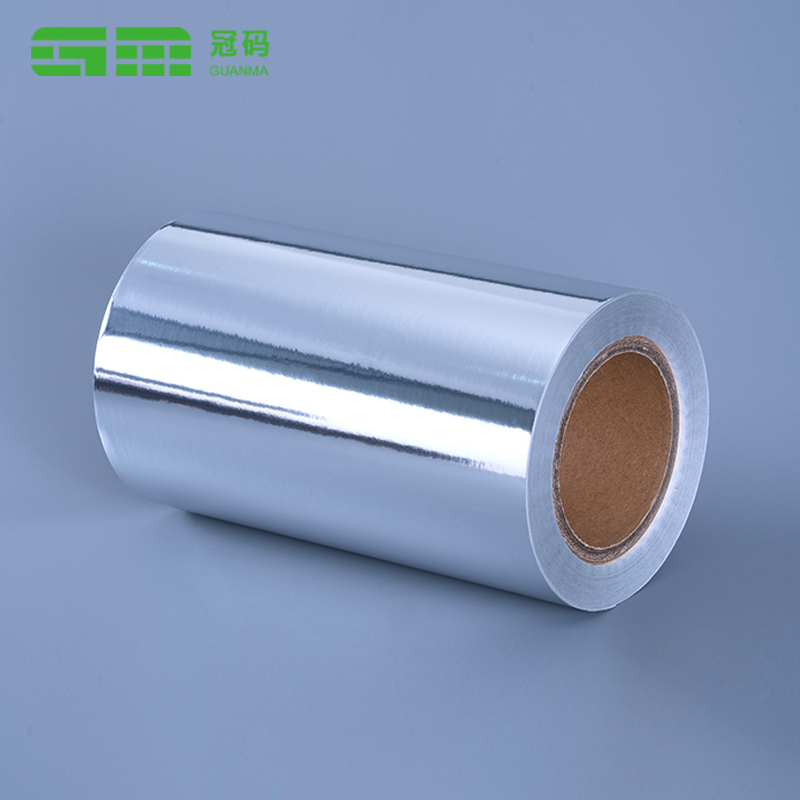

Feb 03,2026Glossy Silver PP, also commonly referred to as Shiny Silver Polypropylene or Metallic Silver PP Film, is a versatile and aesthetically appealing material widely utilized across various industries. This material, essentially polypropylene film with a metallic silver finish, offers a unique combination of visual appeal and practical performance. Its distinctive properties make it a preferred choice for applications ranging from packaging and labeling to decorative purposes.

At its core, Glossy Silver PP is a polypropylene (PP) film. Polypropylene is a thermoplastic polymer known for its excellent chemical resistance, high tensile strength, and relatively low cost. To achieve the glossy silver appearance, the PP film typically undergoes a metallization process. This usually involves vacuum deposition, where a thin layer of aluminum is evaporated and condensed onto the surface of the PP film. The thickness of this metallic layer, along with the smoothness of the underlying PP film, contributes significantly to the final reflectivity and gloss.

The combination of the PP substrate and the metallic layer endows Glossy Silver PP with a range of desirable properties:

Aesthetic Appeal: The most immediate advantage is its bright, reflective silver surface. This high gloss finish provides a premium, eye-catching look that enhances product perception and brand image. It can simulate the appearance of more expensive materials like aluminum foil at a fraction of the cost.

Excellent Printability: Despite its metallic surface, Glossy Silver PP offers good printability. It can be easily printed using various methods, including flexographic, gravure, and offset printing, allowing for vibrant graphics and sharp text. Surface treatments, such as corona treatment, are often applied to improve ink adhesion.

Moisture and Chemical Resistance: As a polypropylene-based material, Glossy Silver PP inherits PP's inherent resistance to moisture, oils, and many chemicals. This makes it suitable for applications where exposure to liquids or certain substances is expected, protecting the packaged contents.

Durability and Tear Resistance: PP is known for its good tensile strength and resistance to tearing, especially compared to paper-based alternatives. This durability ensures that the material can withstand handling and transportation without easily getting damaged.

Dimensional Stability: Glossy Silver PP exhibits good dimensional stability, meaning it retains its shape and size even under varying environmental conditions. This is crucial for applications like labels, where precise registration and fit are necessary.

Barrier Properties: While not a primary barrier material like aluminum foil, the metallized layer provides enhanced barrier properties against gases and light compared to unmetallized PP film. This can help extend the shelf life of certain products by protecting them from UV degradation and oxygen ingress.

Recyclability: Polypropylene is a recyclable material. While the metallized layer can complicate the recycling process slightly, advancements in recycling technologies are making it increasingly feasible to recycle metallized PP films.

Due to its unique blend of properties, Glossy Silver PP finds extensive use in numerous industries:

Packaging: It is widely used for flexible packaging of food products (e.g., snack bags, coffee pouches), cosmetics, and personal care items. Its premium look helps products stand out on shelves.

Labels: Metallic Silver PP labels are popular for product labeling across various sectors, including beverages, health and beauty, and industrial products. The gloss and durability make for attractive and long-lasting labels.

Promotional Materials: Its reflective surface makes it ideal for promotional items, displays, and point-of-sale materials where a high visual impact is desired.

Decorative Applications: Used in crafts, gift wrapping, and other decorative purposes where a shiny, metallic finish is needed.

Automotive and Electronics: In some niche applications, it might be used for interior components or decorative trim due to its aesthetic and durable qualities.

While Glossy Silver PP offers many advantages, it's important to consider certain factors:

Scratch Sensitivity: The metallic layer can be susceptible to scratching, which can mar the aesthetic appeal. Protective coatings are sometimes applied to mitigate this.

Cost: While more economical than pure metallic foils, it is generally more expensive than plain PP films or paper-based materials.

Adhesion: For certain applications, achieving optimal ink and adhesive adhesion on the smooth, low-surface-energy metallic surface might require specific treatments or specialized inks/adhesives.

In conclusion, Glossy Silver PP, with its striking appearance and robust physical properties, continues to be a highly valued material. Its ability to combine visual appeal with practical performance makes it an indispensable choice for manufacturers looking to enhance their product presentation and ensure durability. As technology advances, we can expect further innovations in the production and applications of this versatile Silver Polypropylene Film.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى