Pearl White PP Label: The Smart Choice for Modern Packaging

Feb 25,2026Why Pearl White PP Label is the Go-To Choice for Packaging

Feb 18,2026Why Inkjet Matte White PP is the New Gold Standard for Professional Durable Labeling

Feb 11,2026The Waterproof Standard: Mastering Product Branding with Inkjet Matte White PP Labels

Feb 03,2026In the demanding world of industrial packaging, labels are far more than mere identifiers; they are crucial components that convey critical information, ensure compliance, and reinforce brand identity. For oil barrels, which endure harsh environments and rigorous handling, the choice of labeling material is paramount. Among the various options, pear white PP (polypropylene) stands out as an exceptionally suitable and increasingly preferred material. This article delves into the professional aspects of pear white PP, highlighting why it is an optimal choice for oil barrel labels.

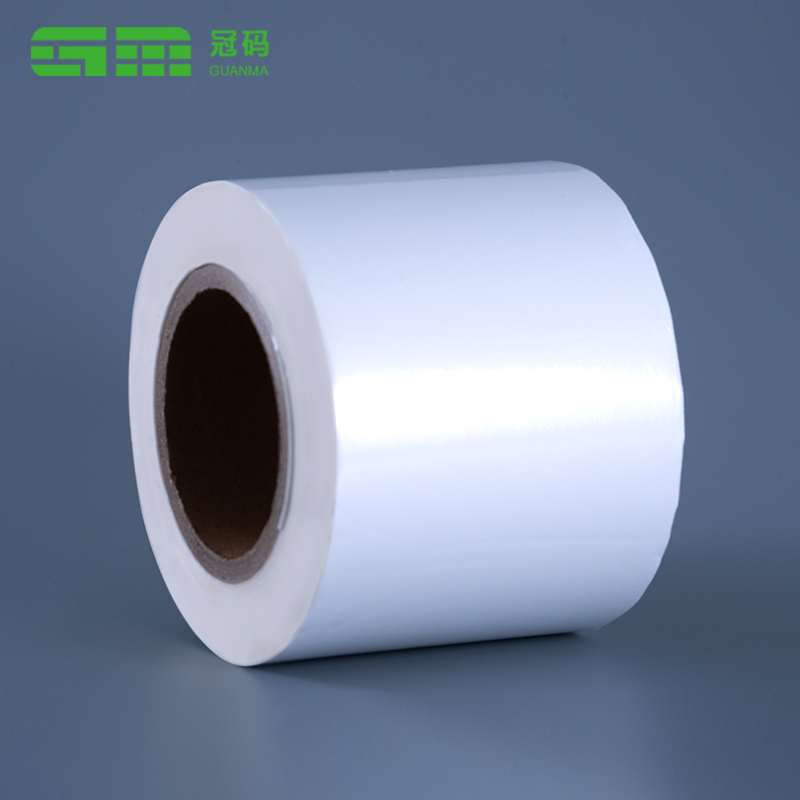

Polypropylene (PP) is a thermoplastic polymer widely recognized for its excellent chemical resistance, durability, and versatility. The "pear white" designation typically refers to a specific type of PP film that offers a distinctive aesthetic—a subtly iridescent, matte, or satin finish that evokes the look of a pearl. This finish is often achieved through a unique manufacturing process that incorporates certain additives or biaxial orientation, enhancing both its visual appeal and functional properties.

The specific characteristics of pear white PP make it exceptionally well-suited for the challenging requirements of oil barrel labeling:

Oil barrels are subject to considerable physical stress, including impacts, abrasions, and vibrations during transport and storage. Pear white PP labels exhibit high tensile strength and tear resistance, ensuring they remain intact and legible throughout the barrel's lifecycle. This inherent robustness prevents premature peeling, tearing, or damage, which is critical for maintaining regulatory compliance and product traceability.

One of the most vital attributes for oil barrel labels is their ability to withstand exposure to various chemicals, oils, greases, and solvents. Pear white PP boasts excellent chemical inertness, meaning it will not degrade, discolour, or lose adhesion when splashed or submerged in petroleum products or common industrial cleaning agents. This resistance guarantees that critical information, such as product type, safety warnings, and batch codes, remains clear and unaffected.

Oil barrels are often stored outdoors or in environments with fluctuating humidity and potential for water exposure. PP is inherently hydrophobic, meaning it repels water. Pear white PP labels will not absorb moisture, preventing bubbling, wrinkling, or the breakdown of the adhesive. This water resistance is essential for maintaining label integrity in all weather conditions.

Beyond its functional advantages, the "pear white" finish offers a premium and clean aesthetic. In an industrial context, a visually appealing label can significantly enhance brand perception and professionalism. The subtle sheen of pear white PP can make a label stand out, conveying quality and attention to detail, even on an industrial container. It also provides an excellent base for high-quality printing, allowing for vibrant colors and sharp graphics.

Pear white PP surfaces are highly receptive to various printing technologies, including flexographic, digital, and thermal transfer printing. This ensures that text, barcodes, QR codes, and graphical elements are reproduced with exceptional clarity and precision. For oil barrels, where legibility of safety data sheets (SDS) information, hazard pictograms, and product specifications is paramount, superior printability is non-negotiable.

Oil barrels can experience a wide range of temperatures during storage and transit, from freezing conditions to hot climates. Pear white PP maintains its integrity and adhesive performance across a broad temperature spectrum, preventing cracking, shrinking, or delamination due to thermal fluctuations.

While petroleum products themselves raise environmental concerns, the choice of labeling material can contribute to sustainability efforts. PP is a recyclable material, and opting for pear white PP labels can align with broader corporate sustainability initiatives. Furthermore, the durability of these labels means less need for re-labeling, reducing waste over time.

When implementing pear white PP for oil barrel labels, several factors should be considered to maximize performance:

Adhesive Selection: Pairing pear white PP with a robust, high-tack adhesive specifically designed for challenging surfaces and harsh environments is crucial. Adhesives with strong initial tack and long-term adhesion are essential to prevent label detachment.

Surface Preparation: Ensuring the oil barrel surface is clean, dry, and free of contaminants before label application will significantly improve adhesion.

Label Design and Layout: Optimizing the label design to clearly display all necessary information, using appropriate font sizes and clear graphics, is vital for functionality and compliance.

Regulatory Compliance: Ensure the label design and material comply with all relevant industry standards and regulations for the transport and storage of petroleum products (e.g., GHS, DOT, IMO).

For oil barrel labels, where durability, chemical resistance, and information integrity are paramount, pear white PP emerges as an outstanding material choice. Its robust physical properties, combined with its resistance to harsh chemicals, water, and temperature extremes, ensure that labels remain legible and intact throughout the product's journey. Furthermore, its aesthetic appeal contributes to a professional brand image. By selecting pear white PP, manufacturers and distributors can ensure the long-term performance and compliance of their oil barrel labeling, ultimately enhancing safety, efficiency, and brand reputation in the demanding industrial landscape.

We have a professional R&D team and strong manufacturing capabilities to ensure product quality and delivery while doing a good job in product iteration and innovation.

Address : Building 2. No.111 Xincheng Road, Xitangqiao Street, Haiyan, Jiaxing, Zhejiang Province, China

Phone: +86-150 0573 0249

Tel: + 86-0573-8685 2732

Fax: + 86-0573-8685 2732

E-mail: [email protected]

Copyright© Zhejiang Guanma Packaging Co., Ltd.

Privacy

Privacy

OEM Self Adhesive Label Material Manufacturers Waterproof Labels Suppliers Custom Adhesive Label Material Factory

English

English русский

русский Español

Español عربى

عربى